Where Quality Meets Innovation

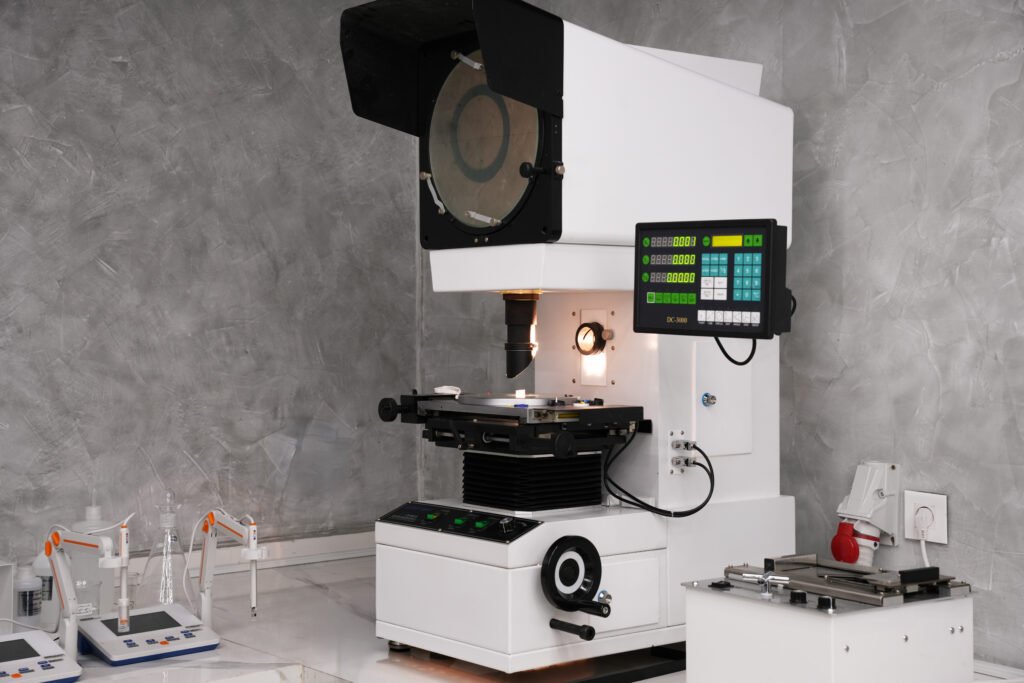

At Astro Power Cables, our commitment to excellence is powered by our people and backed by technical precision. The Cable Lab — our in-house quality assurance and testing hub — plays a vital role in ensuring that every cable we produce meets the highest performance, safety, and compliance standards

Driven by Technical Excellence

Routine, sample, and type tests on copper and aluminum cables to ensure durability, accuracy, and adherence to international benchmarks.

Routine Tests

Sample Tests

Type Tests

What Are Type Tests?

Type tests are a series of laboratory tests carried out on a cable design to verify that it meets the requirements of international standards (such as IEC ) for safety, reliability, and performance.

Unlike routine or sample tests, which are performed on every production lot or sample pieces, type tests are performed on a prototype cable design and repeated only when the design, materials, or manufacturing process significantly change. They are conducted under controlled conditions and simulate the most demanding operating and environmental stresses the cable may encounter.

Why Are Type Tests Important?

01

Demonstrate full compliance with IEC and national standards

02

Give customers confidence in safety, durability, and performance

03

Ensure consistency when any change occurs in cable design or materials

04

Serve as proof of conformity for tenders, audits, and certifications

What Are Type Tests?

At our in-house lab, we’re equipped to perform full type testing for low-voltage power cables, including:

- Conductor resistance test at 20 °C

- Measurement of thickness and overall dimensions

- Pressure test at high temperature on insulation

- Hot set test on XLPE insulation

- Aging tests on insulation and sheath materials

- Shrinkage and thermal stability tests on materials

- Additional electrical tests as required for compliance

- Tensile strength and elongation at break of insulation and sheath (before and after aging)

Astro’s technical experts bring deep industry experience, supporting clients with cable customization — whether you’re working on infrastructure, industrial, or energy projects.

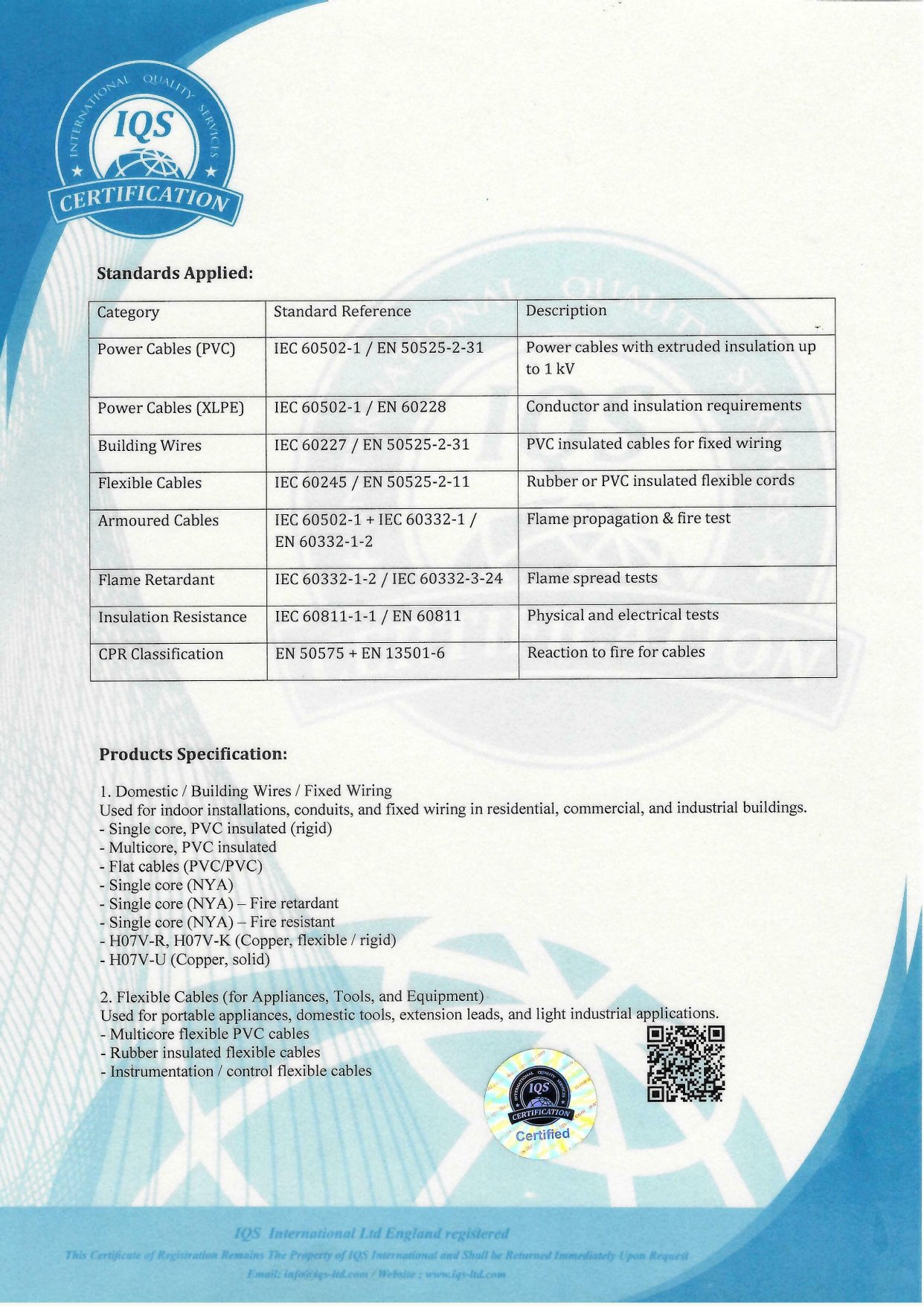

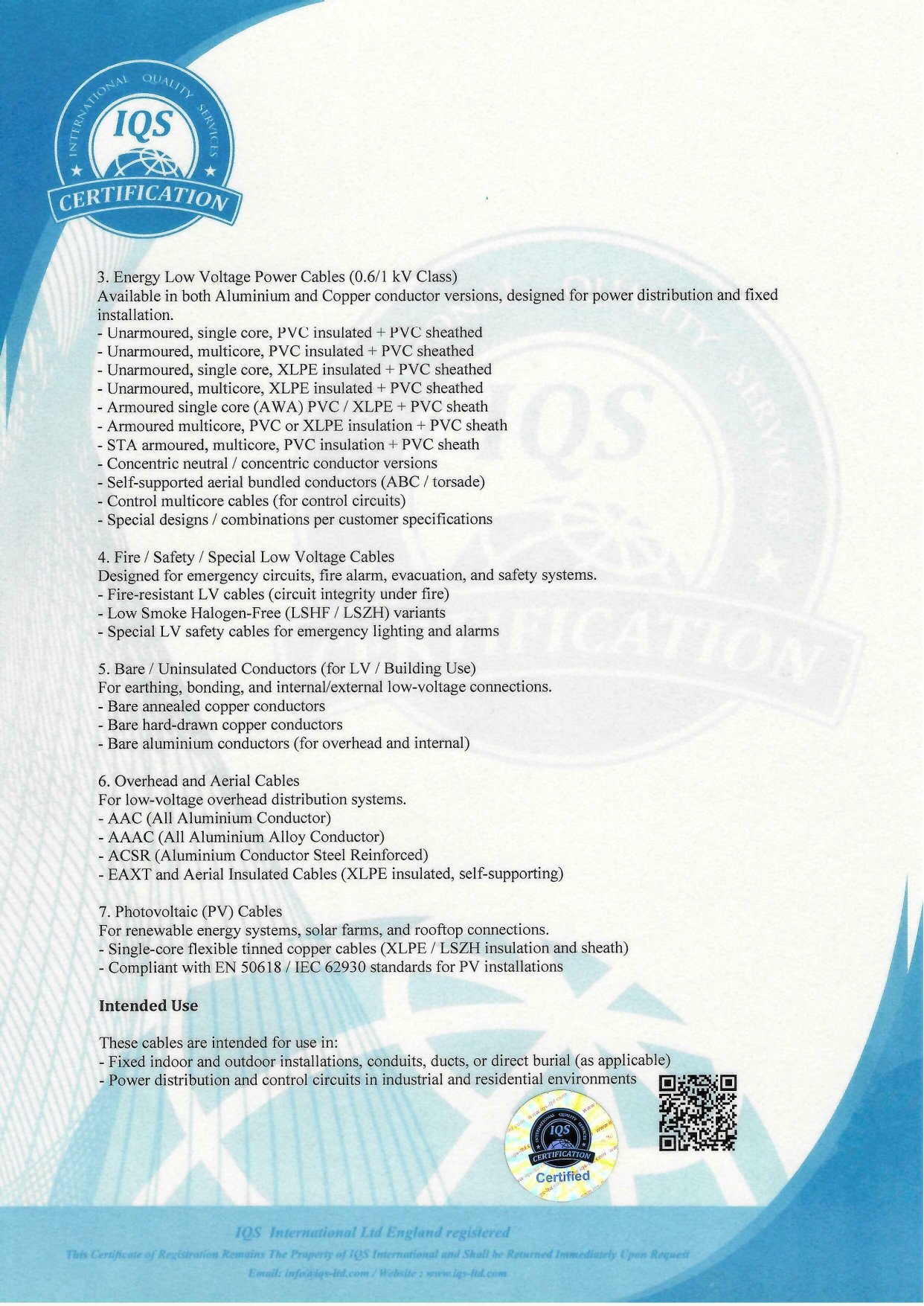

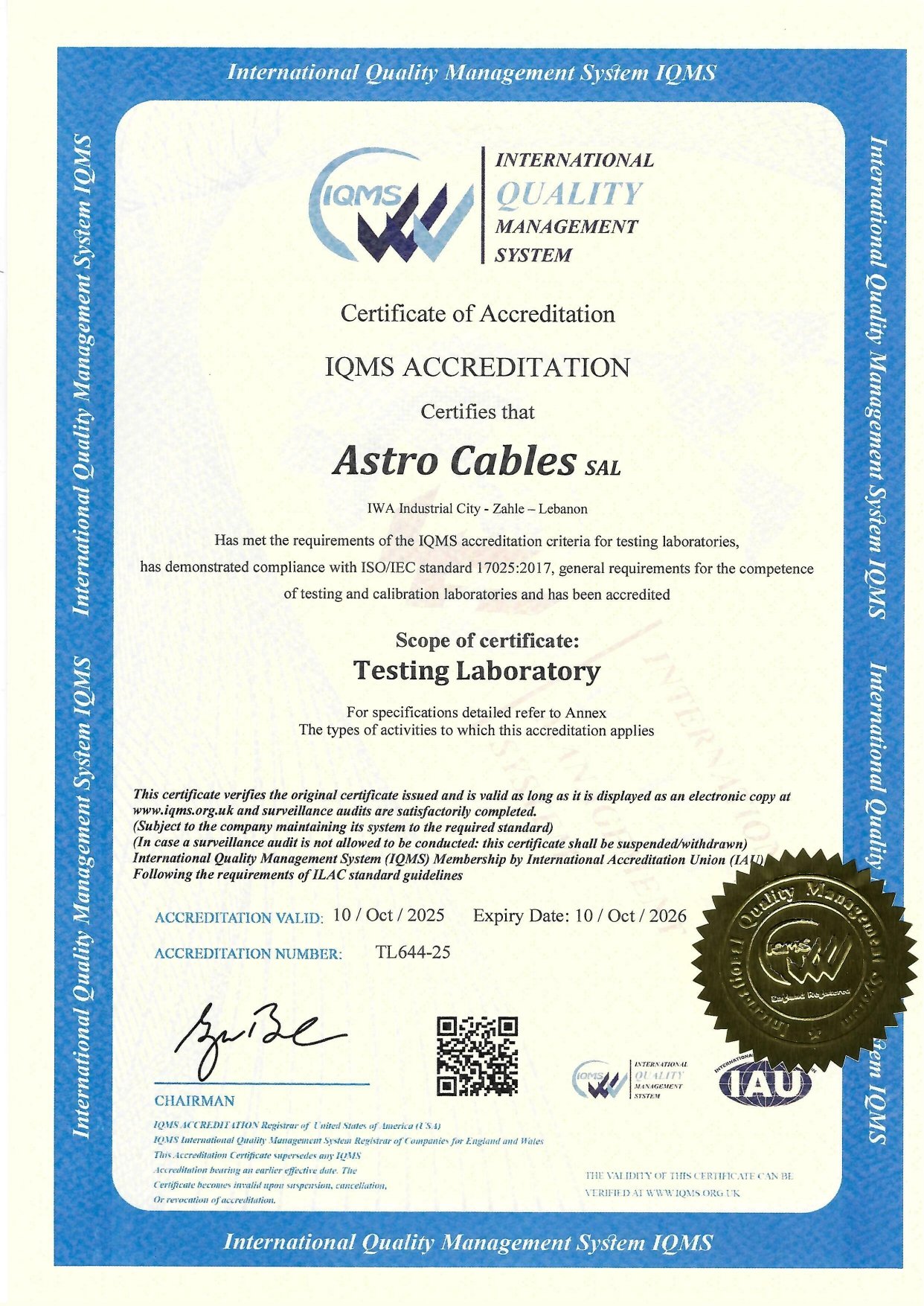

All our testing is backed by globally recognized certifications:

Quality Management System Certification, ensuring consistency and continuous improvement across all processes.

Environmental Management System Certification, reflecting our dedication to sustainable and responsible manufacturing practices.

Occupational Health and Safety Management System Certification, highlighting our commitment to employee safety, risk prevention, and a healthy work environment.

Conformity with European product safety, quality, and performance standards, confirming that our cables meet EU requirements for construction and electrical applications.

Astro Power Cables’ in-house Cable Lab is accredited under ISO/IEC 17025:2017, verifying its technical competence and reliability in testing and calibration. This ensures every test performed meets international quality and accuracy standards.